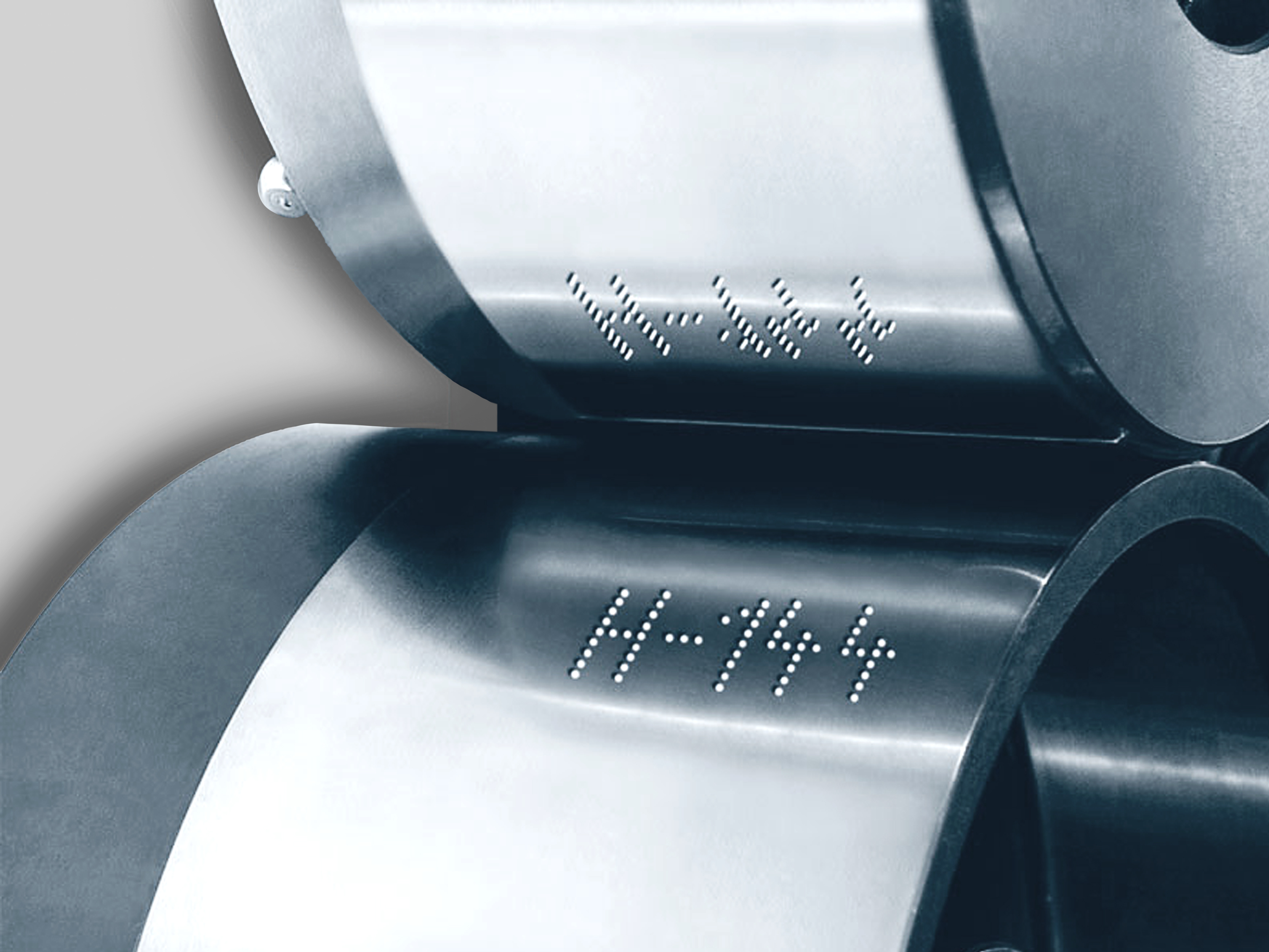

Micro punching for functionality & design

Precise micro perforations for packaging and specialty products

Schobertechnologies enables precise micro perforations that meet both functional (e.g. for breathable packaging) and visual requirements. Our rotary systems ensure consistent quality, high speed and maximum process reliability.

Micro-perforations are used, for example, to produce tear-off perforations in stamp booklets. The holes have a diameter of 0.5 mm with a distance of 1.5 mm. A safe waste removal is guaranteed by the use of a hollow die cylinder, with working widths of up to 500 mm. These units can be installed in continuous form printing machines. The drive connection is either mechanical or electronic. Changes to the punching pattern or the addition of safety perforations can be made by simply and safely replacing the punch and die bars.

Micro punching can be used for surface perforations for tea sticks as well. This new type of packaging for tea consists of a laminate (aluminum, PE and PET) with a very narrow punching pattern (holes in a row with a diameter of 0.5 mm). Schobertechnologies supplies punching modules or the complete film punching machine with print mark control for up to 4 patterns across to the running direction.