Combi punching for maximum flexibility in processing

Efficient combination of punching technologies

With Schober’s combi punching systems, different processes can be combined in a single, flexible production step. The result: higher efficiency, short setup times and precise results – ideal for labels, packaging and specialty products.

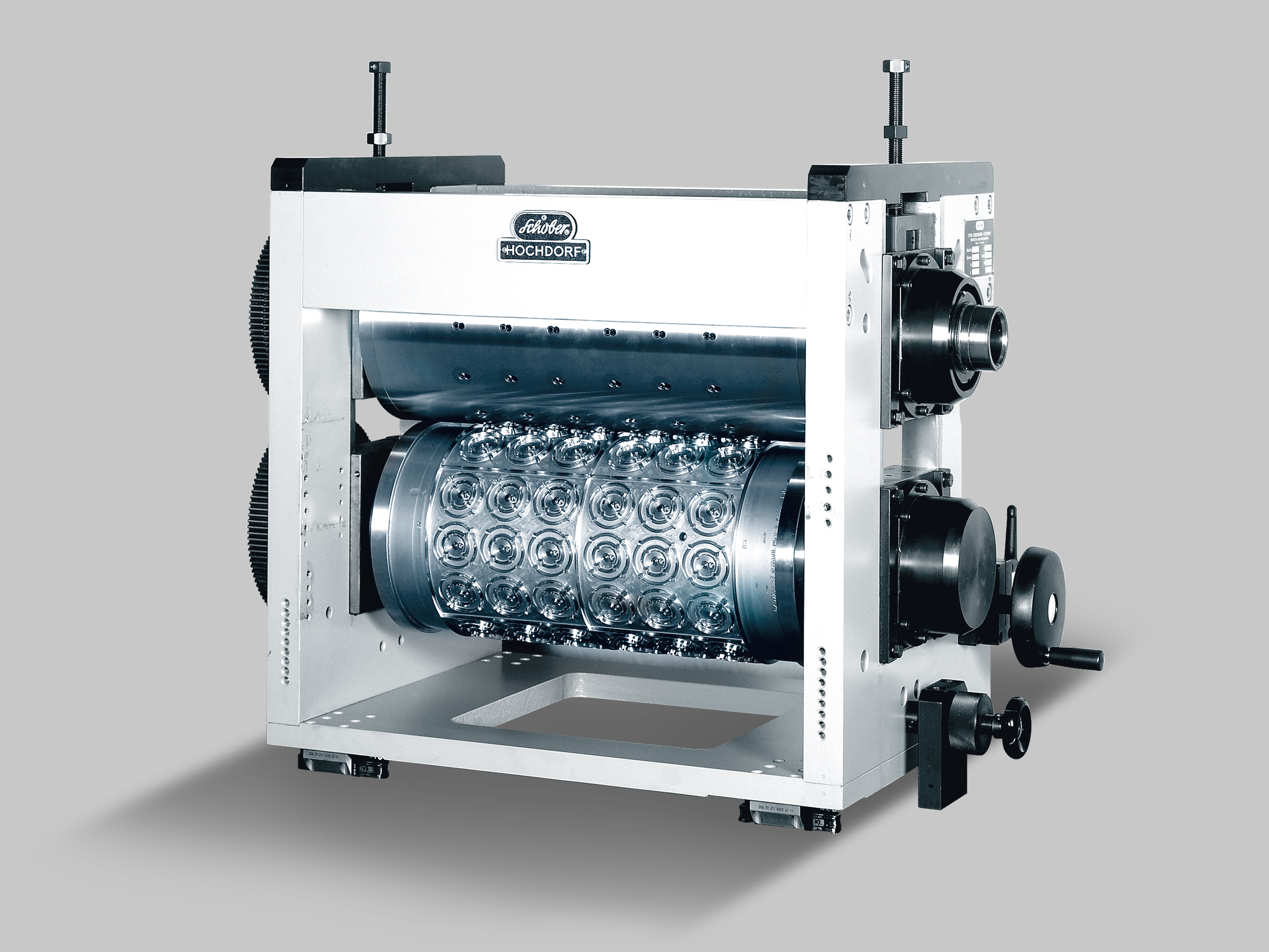

Combined punching modules are used when tight tolerances between length cutting and shape punching / corner rounding are required (e.g. in the production of tea labels and tea bags). The positioning of the module or tools is achieved by precise cross adjustment.

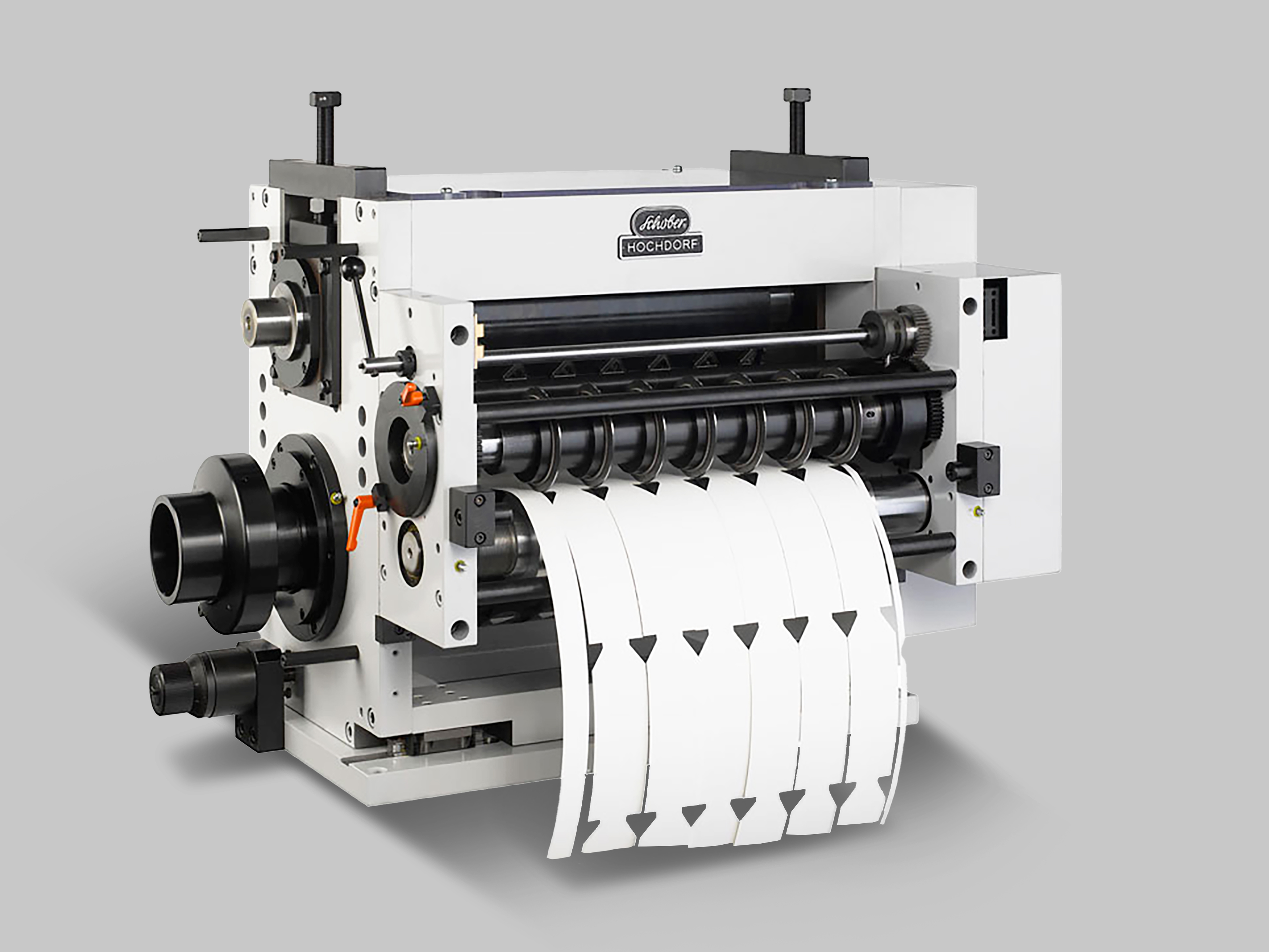

When setting up the machine, the cutting blade set can be removed with a single movement. The complete blade set is positioned precisely and securely using an eccentric lever. The slitting station can also be integrated into existing machines, such as label printing machines or similar.