Scissor cutting for clean edges and precise results

High-quality cuts even at high production speeds

With Schober’s scissor cutting technology, you achieve clean cut edges and precise results even at high production speeds. The process is suitable for a wide range of materials such as films, paper or carton, ensuring consistent quality and efficiency in production.

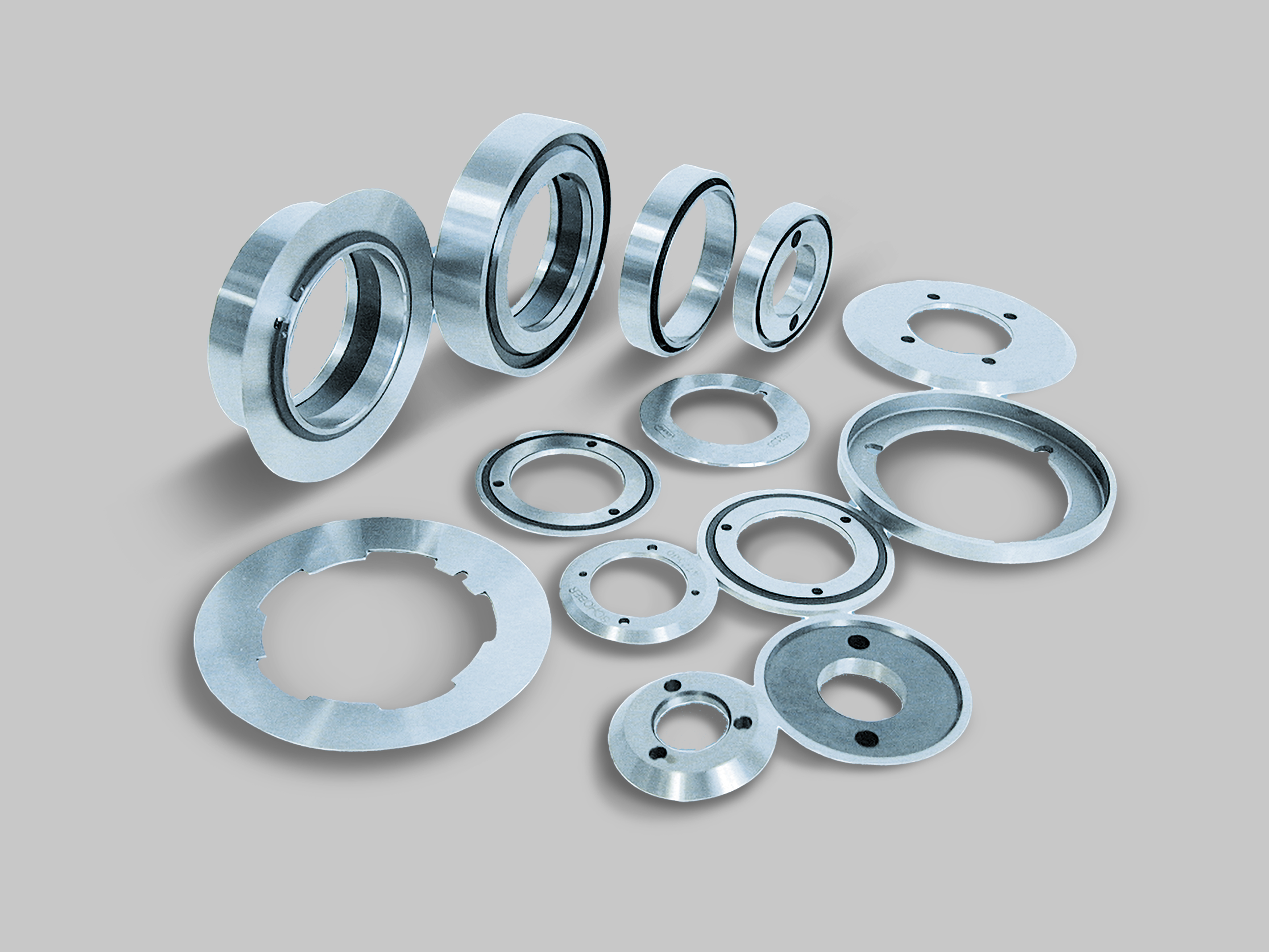

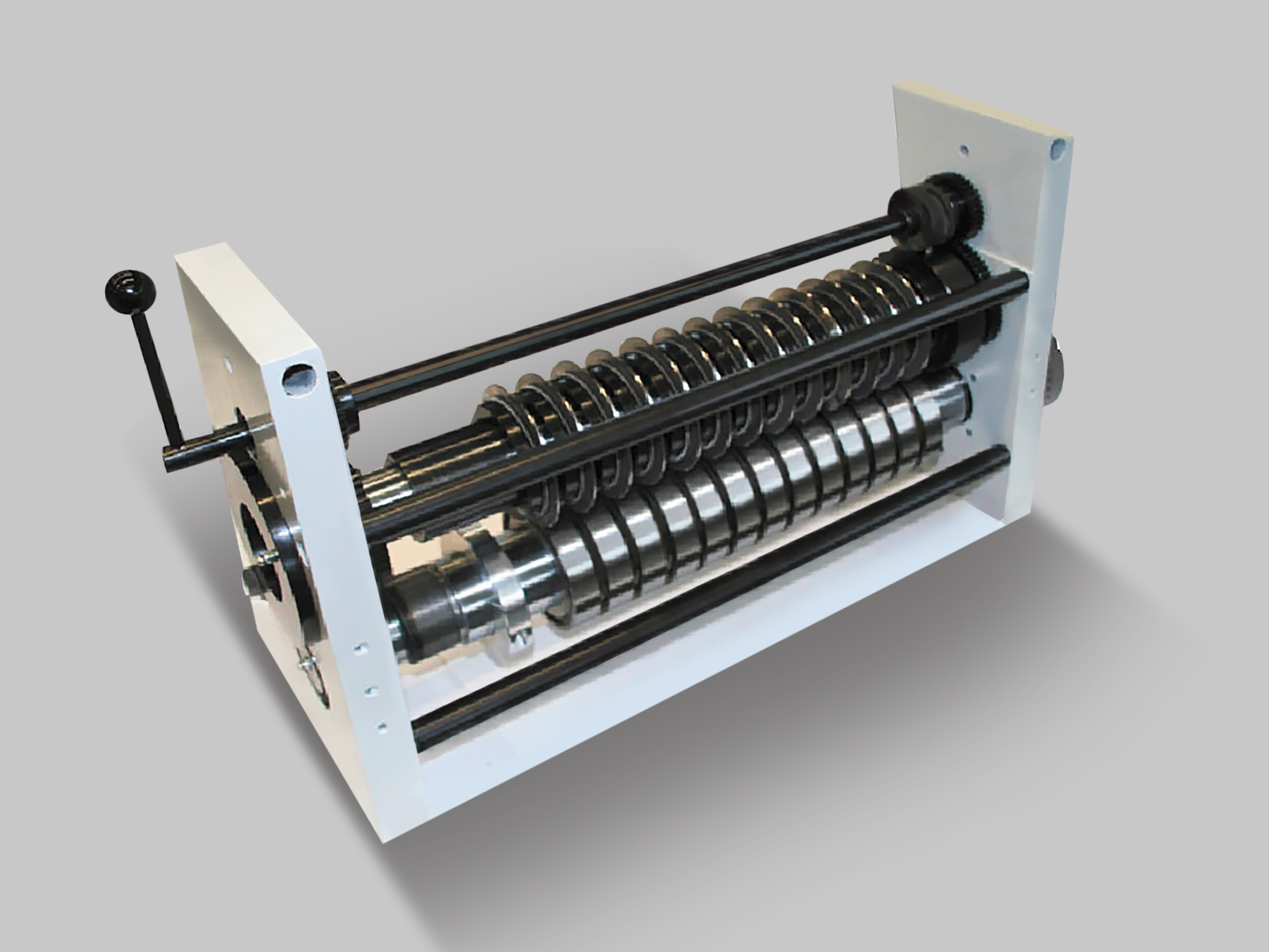

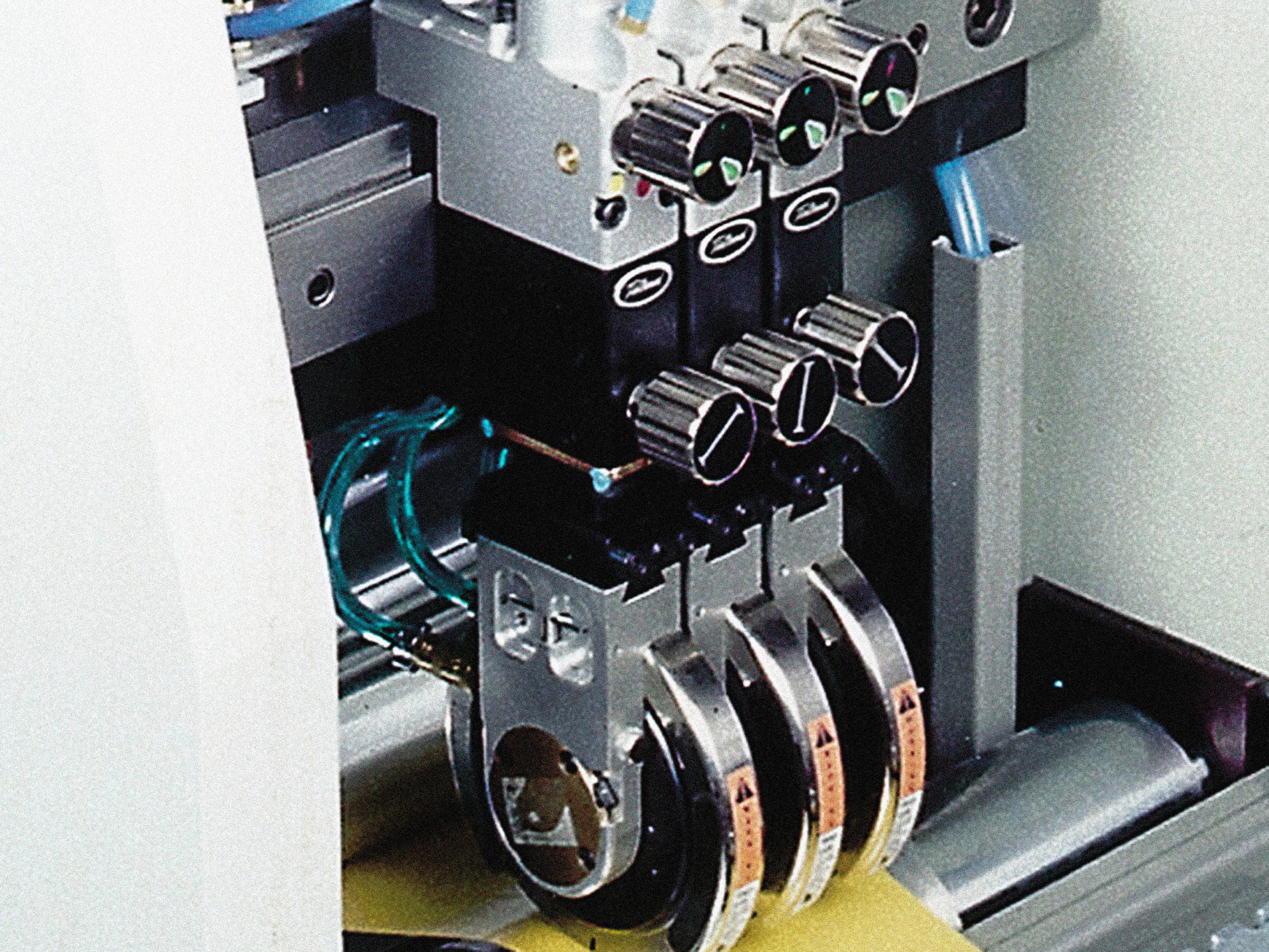

During the scissor cut, the upper knive interlocks with the cutting edge of the bottom knive and is pressed against it by a spring. The targeted shearing of the material produces a smooth cutting edge. This type of knife is used in continuous form and label printing machines, high-performance slitter rewinders and in production lines with high-performance slitting systems for processing paper, films, laminates and cardboard. Schobertechnologies supplies top cutting knives from stock. Lower cutting knives and cutting knife holders can be supplied promptly. Units for holding the knives are manufactured to customer specifications if required. Grinding machines are also available for grinding circular knives on site.

During the scissors cut the upper knife is pressed with a spring against the edge of the lower knife. Due to the shearing process a smooth cutting edge is created.

This knife system is mainly used to convert paper, foil, laminates and cartons in continuous forms and label printing machines, high performance slitters as well as special converting systems with high performance cutting systems.

Schobertechnologies supplies the scissor cutting knives from stock. Counter knives and knife holders can be supplied on short notice. Taylor made modules for the fixation of the knife holders can be manufactured on demand.