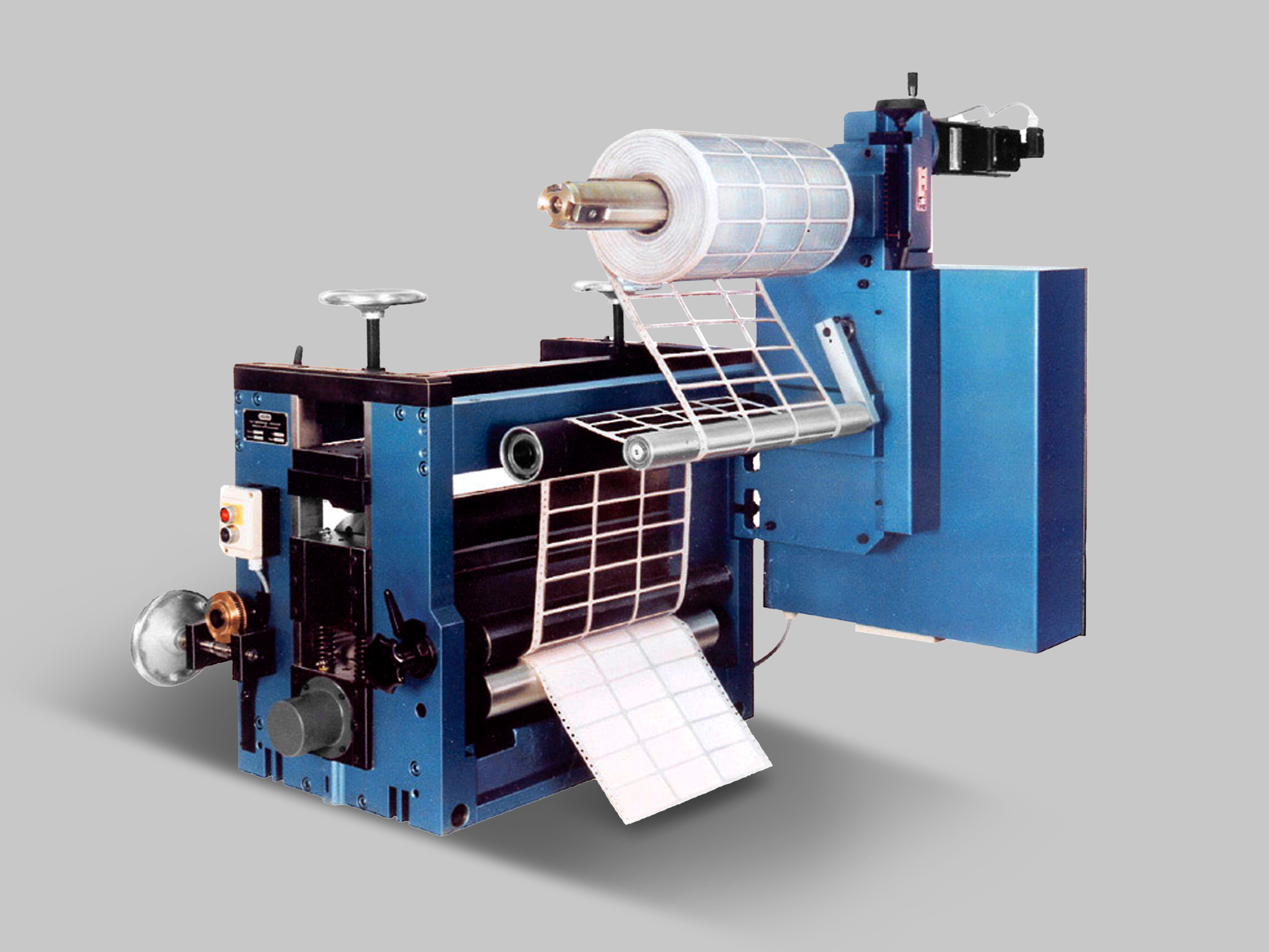

Half cut & kiss cut for flexible material processing

Precise separation without damaging the liner

In half cutting or kiss cutting, material layers are precisely separated without damaging the carrier material. Schobertechnologies ensures maximum accuracy, long tool life and efficient production – ideal for the label and packaging industry.

Half cuts (e.g. for opening aids or self-adhesive labels) are used for the targeted cutting or perforation of single-layer or multi-layer materials, which can also be equipped with barrier properties. During the ingate only a part of the material thickness will be cut. Since thin materials are also often cut, precise infeed is required.

The micrometrically accurate infeed takes place via conical guide rings (Gap Control System) or electronically via a backlash-free spindle system.